Bioprinting & Tissue Engineering Advances

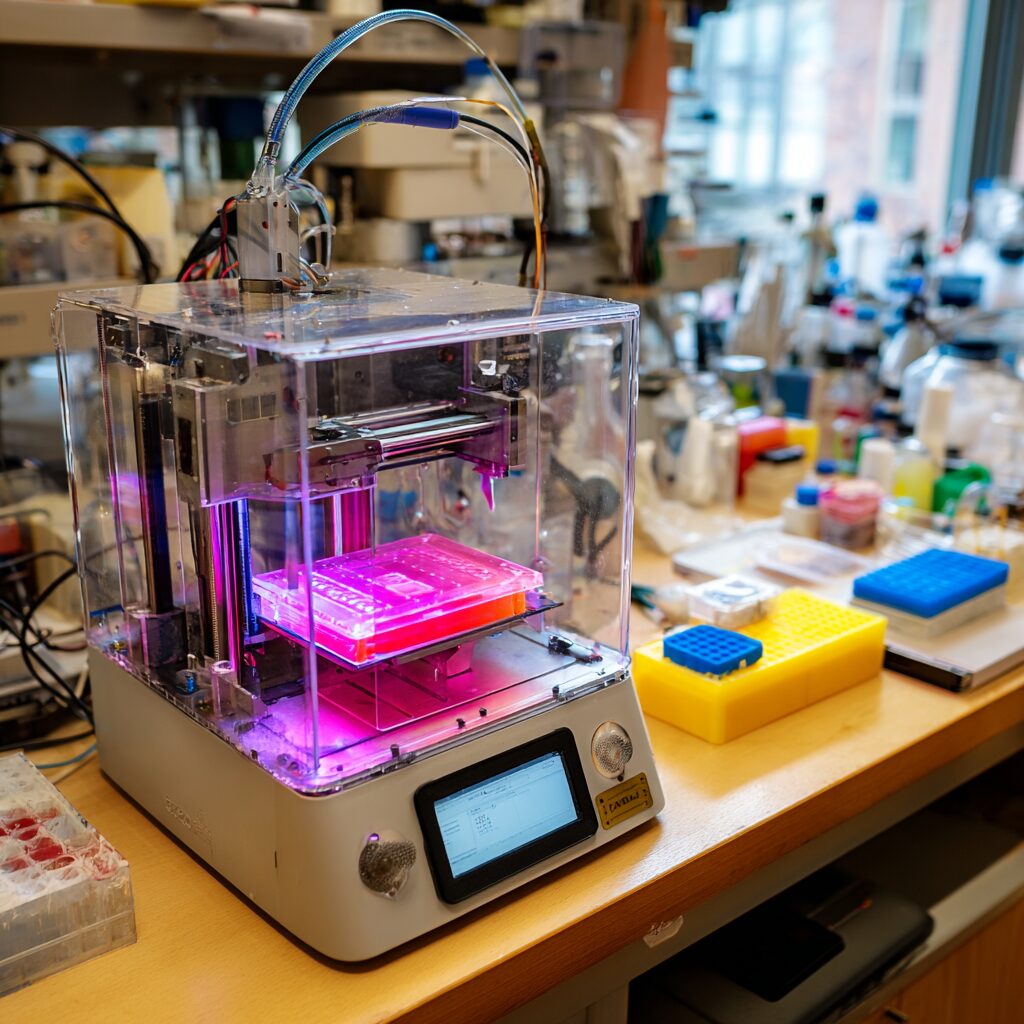

1. MIT’s New Bioprinting Technique Improves Engineered Tissue Production

In a groundbreaking development, researchers at MIT introduced a faster and more precise bioprinting technique that enhances how engineered tissues are fabricated. This method allows for layer-by-layer deposition of cells with increased control, speeding up the process while maintaining structural fidelity. This advancement is critical for printing tissues that need to replicate the complex architecture of native organs, bringing us closer to bioprinted organs suitable for real-world transplantation and clinical use.

2. Texas A&M’s Living Lung Cells for Extreme Environments

Scientists at Texas A&M have successfully 3D bioprinted lung tissue models that can survive in high-pressure and high-temperature environments. These lung cell models are being used to simulate realistic respiratory responses in extreme conditions, which is vital for aerospace medicine, spaceflight safety, and pulmonary research. This work is opening new frontiers in off-world health diagnostics and climate-related respiratory disease modeling.

3. Cancer Research Enhanced by Organoids and Microfluidics

A fusion of bioprinting, organoids (mini-organs), and microfluidic chips is enabling scientists to recreate tumor environments in the lab. These models provide a more accurate representation of how cancers form and grow, allowing for earlier detection methods, personalized drug testing, and precision oncology treatments. This approach reduces the reliance on animal models and allows researchers to simulate tumor behaviors on patient-specific tissues.

🔗 Learn more at Medical Xpress

4. Bioprinting Layered Artificial Blood Vessels

One of the biggest challenges in printing large organs is creating vascularized tissues — tissues that can carry blood. Researchers have developed layered artificial blood vessels using advanced bioprinting techniques, marking a major step toward solving this problem. These vessels are capable of mimicking the mechanical and functional properties of real blood vessels, including the ability to stretch and withstand flow pressure, making them ideal for future use in transplantable organs.

5. Stanford’s Algorithm for Complex Vascular Networks

Stanford engineers have developed new design algorithms to replicate the intricate vascular networks found in the human body. These algorithms can be used to 3D-print microvascular channels that are essential for keeping printed organs alive post-transplant. The breakthrough enables scalable designs for heart tissue, liver lobules, and kidney nephrons, making full-organ bioprinting more feasible.

🔗 See more at 3D Printing Industry

6. U.S. Army’s Vascularized Liver Tissue Model

Scientists at the U.S. Army’s Medical Research Institute of Infectious Diseases (USAMRIID) have developed a vascularized 3D bioprinted liver model that can be used to simulate liver function, disease, and toxin exposure. This model supports both biomedical research and biodefense applications, including responses to chemical and biological warfare agents.

7. FDA Clears First Bioprinted Nerve Repair Device

3D Systems, a pioneer in 3D printing, recently received FDA approval for its bioprinted peripheral nerve repair technology. This is a major milestone — not just for research, but real-world therapeutic use. The approved product uses custom bioprinted scaffolds to guide nerve regeneration, offering new hope to patients suffering from traumatic nerve injuries and paving the way for bioprinted medical devices to become standard in surgical practice.

🔗 Read the breakthrough on Med-Tech Insights

🌱 Trends & Materials Innovation in Bioprinting

Stimuli-Responsive & Smart Bioinks

The next generation of bioinks is being developed to respond to external stimuli — such as pH, temperature, or magnetic fields. These “smart” bioinks mimic tissue environments more effectively, improve cell viability, and offer better mechanical strength and printability. These innovations are essential for printing tissues that function like their natural counterparts.

🧠 Next-Level Research Highlights

AI + Bioprinting Synergy

AI is now being embedded directly into bioprinting workflows. Algorithms assist with:

-

Print quality control

-

Cell behavior prediction

-

Optimizing print paths for complex tissues

This synergy is making bioprinting more scalable, reliable, and patient-specific.

Smart Hydrogels for Regenerative Medicine

“Smart” hydrogels are materials that respond dynamically to their environment. In recent studies, these materials are being used to support bone regeneration, create realistic liver cancer models, and act as scaffolds for muscle and vascular tissue engineering.

Bioinks Keep Evolving

Research continues into refining the composition of bioinks to better support various cell types, enhance structure, and maintain shape after printing. Current goals include:

-

Supporting larger, multi-cellular constructs

-

Improving biocompatibility and degradation rates

-

Enhancing the functional integration of printed tissue with host tissues

🔗 Phys.org

📌 Big Picture: What It All Means

-

✔ Lab to Clinic: Research is transitioning into real-world medical applications faster than ever.

-

✔ From Tissues to Whole Organs: Layered blood vessels and smart scaffolds are tackling key hurdles.

-

✔ Clinical Breakthroughs: FDA approvals for nerve repair suggest bioprinting is no longer theoretical.

-

✔ Interdisciplinary Expansion: Aerospace, oncology, AI, and biodefense are all integrating bioprinting tech.

Leave a Reply